Material

The best known reinforcing fibres are glass fibres, aramide fibres and carbon fibres. Carbon fibres are produced by pyrolysis of unmeltable carbon polymer threads fibre. The original fibrethreads contain a continuous carbon chain (-C-C-C-C-C-). The final product consists of 95% pure carbon.

In connection with resin these fibres are glass fibre reinforced plastic, aramide fibre, and carbon fibre reinforced plastic. Shaping takes place in special tools when the fibres are joined with the plastic.

Carbon fibre reinforced plastic stretches fully elastically . Resistance to fatigueand vibration damping are excellent. The thermal expansion coefficient is low and negative. By means of a corresponding design, components can be made virtually without any thermal expansion.

The high unisotropy of a fibre reinforced plastic is decisive for design and construction of a component. The strength values are outstandingly good in longitudinal direction, however, they are bad transversely.

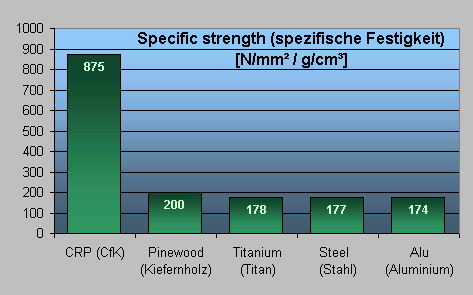

skilful component design makes use of the advantages and minimizes the disadvantages. For unidirectional load the mass specific strength is five times higher than for steel (see diagram).